Compactobar – Compaction Measuring System for Paver (Roller)

210 2519273

info@mobact.gr

Press here

This is perhaps the most user-friendly instrument we have ever built.

A quick glance at the light scale immediately gives the operator the compression value (CMV)

What is important is recorded

If you know where you are and have stored all the CMV values for each point, you can relax. The instrument can be connected to a printer and a control per lane can be printed during compression passes.

This makes it easy to then find areas of poor compaction that may need additional passes or areas where reinforcement work needs to be done. Weak points that require testing can also be identified.

The contractor is able to check the quality of each layer in detail. The contractor can present and document the compaction result to his client. Surfaces that have low compressibility are immediately indicated and can be improved.

From his position, the operator can have full control over the compression results. It can reduce the number of passes to the minimum number necessary until the desired CMV values are reached, thus saving time and money.

When the light starts flashing, this is a warning that danger for the double jumps is fast approaching. Thus, the life of the drum is extended, and the risk of breakage of the surface material is reduced.

The CompactoBar is a reliable system derived from two of our products: The Compaction Indicator and Compactometer.

All that is required is a vibration sensor (A-sensor) and the main electronic unit for signal processing, light presentation, and printing.

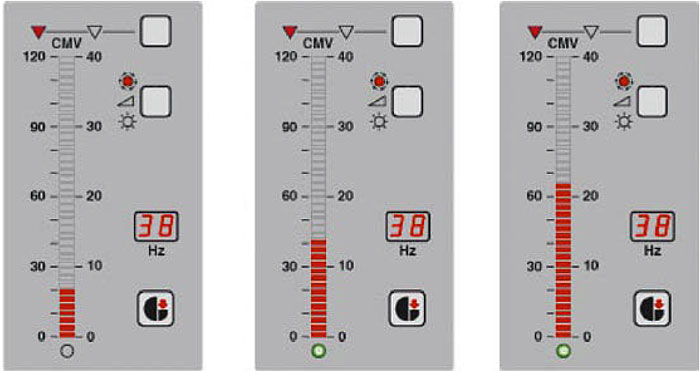

Example: let the desired CMV compression value be 40. The scale on the left shows a CMV value = 20. This means that a few more passes are necessary. The middle scale shows that the desired value of CMV=40 has been reached, and the green light below is on. In the scale on the right, we notice that too many unnecessary passes have been made.

or information and we will get back to you as soon as possible.

or information and we will get back to you as soon as possible.