For many decades, pile driving has been the dominant way of guiding earthmoving machinery in construction operations. The stakes, as natural points of reference, allowed the determination of levels and height differences in the works. However, this method had significant limitations, being time-consuming and prone to human error. The advent of Laser systems has revolutionized the way earthworks are now carried out, offering unparalleled precision and efficiency.

The Laser systems have made traditional dowels almost obsolete, especially in applications that require stable slopes and high precision. Especially in projects such as paving for industrial buildings, parking lots, stadiums or even fields, Laser Automation Systems offer a top solution.

The main reason that Laser Systems have become the new standard technology in these projects is their ability to offer exceptional accuracy and automation. The project machinery (Excavator, Grader, Dozer, Loader, etc.) equipped with the appropriate Laser equipment, can automatically form the desired surface, eliminating the need for manual checks and corrections.

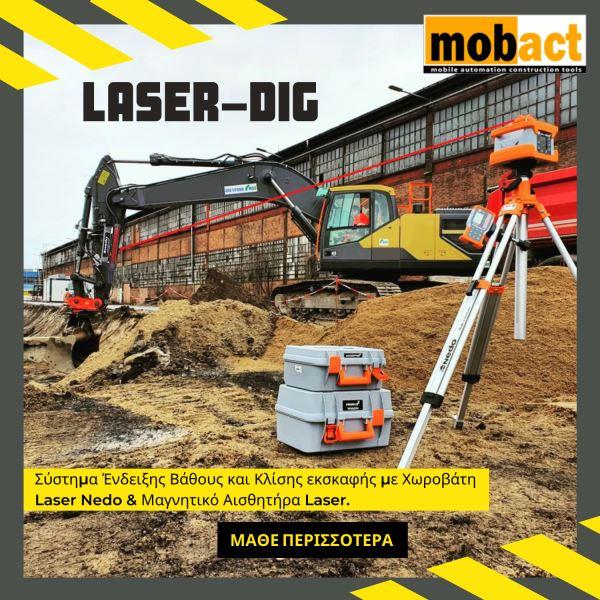

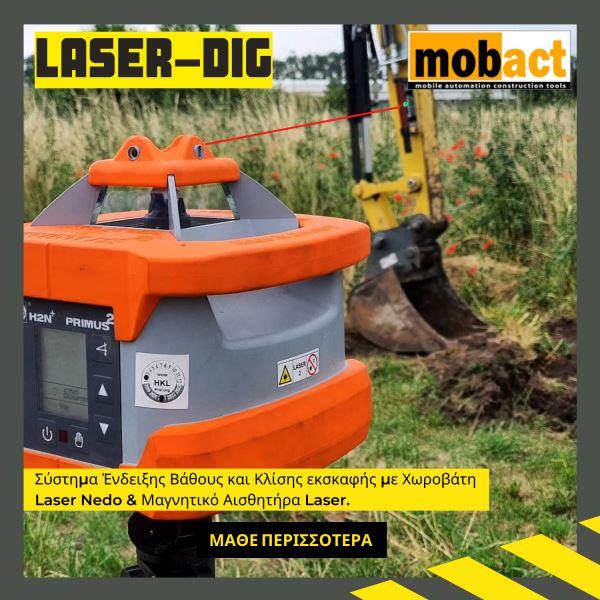

The operation of Laser systems is simple, but impressively effective. At each construction site, a Laser Pathfinder is placed at a central point. This Laser creates a horizontal or inclined reference plane that serves as a guide for leveling machines.

These machines are equipped with Laser receivers, which track the position of the Laser in real time. As the machine moves, the Laser System automatically controls the elevations of the surface being formed, ensuring that the material is laid with absolute precision. The operator mainly undertakes the management of the course and the material, while the Laser system undertakes the precise shaping of the surface.

Laser Automation Systems are ideal for projects that require stable slopes and perfectly flat surfaces. In applications such as:

Laser Automation Systems offer a number of advantages that make them irreplaceable in many applications:

Laser Automation Systems have changed the way earthmoving operations are performed, especially on projects that require stable slopes and flat surfaces. This technology offers precision, speed and cost reduction, making it the ideal choice for projects such as industrial buildings, parking lots, stadiums and fields.

The transition from piles to Laser Systems is inevitable for those who wish to remain competitive and execute projects with maximum efficiency and accuracy.